Menu

Products

Horizontal lathe

High Speed Precision Lathe

Precision Heavy-Duty Lathe

Heavy-Duty Lathe

PC Base

CNC Lathe Machine

Vertical Machining Center

Linear Way

Box Way

Gearhead Way

High Speed Bridge Type

Rack Hobbing Machine

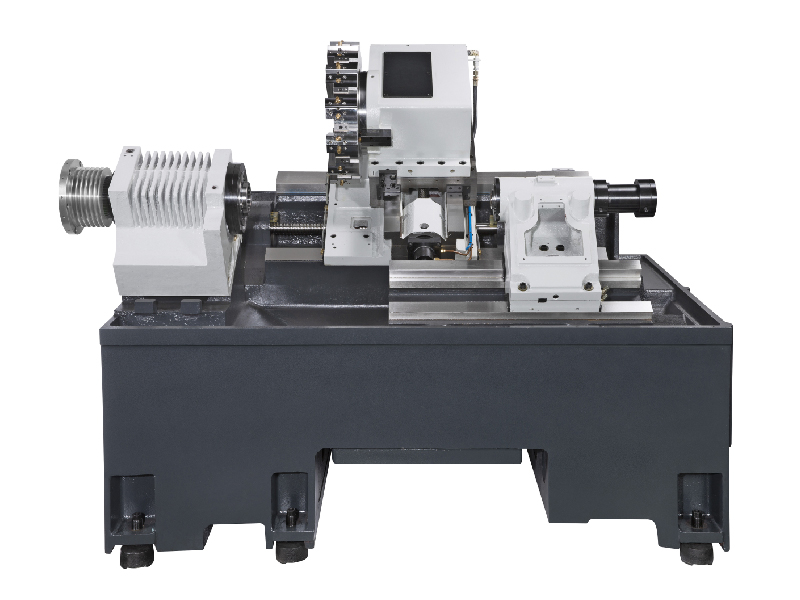

JG-200(L)/250(L)

home > products > CNC Lathe Machine > JG-200(L)/250(L)

-

- Ergonomic operation.

- Use Meehanite Casting, be grinded accurately, and be made by high-frequency heat treatment.

-

SPECIFICATIONS Unit Lathe Rail type Body type Fanuc controller (8.4") Chuck size inch Ball screw Hydraulic tank capacity L Coolant tank capacity L Processing range Swing over bed*1 mm Max. Turning diameter*1 mm Max. Turning length*1 mm Bar diameter mm Stroke X-Axis mm Z-Axis mm Spindle Spindle nose Spindle bore mm Max. Spindle speed RPM Servo turret Turret capacity Square tool shank mm Round tool shank mm Center height mm Indexing time (tool-tool) mm Indexing time (includes locking) sec Total indexing time for 180° sec Total indexing time for 180°(includes locking) sec Tailstock Tailstock stroke mm Tailstock sleeve stroke mm Tailstock sleeve taper Feeding Rapid feeding speed m/min Motor Spindle motor KW Feed motor KW Servo turret motor KW Machine size (Length x Width x Height)*2 cm Net weight kgs Pallet size (Length x Width) cm JG-200 JG-200L JG-250 JG-250L Box / Linear way 30° Slant 0i-TF ß12 8 10 R40 x P12 58 150 210 150 210 560 350 470 720 470 720 52 75 380 530 780 530 780 A2-6 A2-8 65 91 4,000 12 25 40 150 0.1 0.3 0.7 0.9 350 500 350 500 100 MT#5 X:20, Z:24 11/15 X:1.8, Z:2.5 1.2 320 x 166 x 185 355 x 160 x 180 320 x 166 x 185 355 x 160 x 180 4,100 4,500 4,100 4,500 260*229 280*229 260*229 280*229 ※Specification is subject to change without prior notice.

1※Thickness of jaw, tool and retract room have been reserved.

2※Chip conveyor is included. -

Standard Accessories

- U sleeve ø16,20,25,32 per size 1 pc

- ID sleeve ø6,8,10,12,16,20,25 per size 1 pc

- OD tool holder 2 sets

- ID tool holder 3 sets

- U-drill tool holder 1 sets

- MT#2, 3 sleeve per size 1 pc

- Work light

- Full enclosure

- Heat exchanger

- Auto lubricator

- Hydraulic chuck (1 set hard jaw, 3 sets soft jaw)

- Programmable tailstock

- Side type chip conveyor (with tank)

- Tool box with tool kits

Optional Accessories- Auto door

- Auto bar feeder

- Air-conditioner

- Tool probe

- Oil-water separator

- Oil skimmer

- Part catcher