Menu

Products

Horizontal lathe

High Speed Precision Lathe

Precision Heavy-Duty Lathe

Heavy-Duty Lathe

PC Base

CNC Lathe Machine

Vertical Machining Center

Linear Way

Box Way

Gearhead Way

High Speed Bridge Type

Rack Hobbing Machine

JG-200(L)CS/JG-250(L)CS

home > products > CNC Lathe Machine > JG-200(L)CS/JG-250(L)CS

-

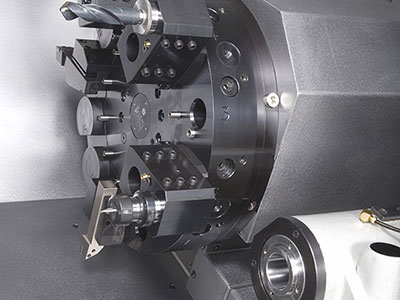

- Combine C-axis control and live turret becomes a turning and milling compound center. Multiple tasks could be processed on a single workpiece by a single machine which could avoid the errors due to movement of workpiece between machines and also save processing time and manpower.

- Live turret is driven by an AC servo motor to provide ample power, in the form of torque, to complete the tough processing.

-

SPECIFICATIONS Unit Lathe Rail type Body type Fanuc controller (8.4") Chuck size inch Ball screw Hydraulic tank capacity L Coolant tank capacity L Processing range Swing over bed*1 mm Max. Turning diameter*1 mm Max. Turning length*1 mm Bar diameter mm stroke X-Axis mm Z-Axis mm Spindle Spindle nose Spindle bore mm Max. Spindle speed RPM German Sauter Live turret Turret capacity Square tool shank mm Round tool shank mm Center height mm Indexing time (tool-tool) sec Tailstock Tailstock stroke mm Tailstock sleeve stroke mm Tailstock sleeve taper Feeding Rapid feeding speed m/min Motor Spindle motor (wide) KW Feed motor KW Servo turret motor KW Machine size (Length x Width x Height) *2 cm Net weight kgs Pallet size (Length x Width) cm JG-200CS JG-200LCS JG-250CS JG-250LCS Box / Linear way 30° Slant 0i-TF αP15 8 10 R40 x P12 58 150 210 150 210 560 350 400 650 400 650 52 75 330 420 670 420 670 A2-6 A2-8 65 91 4,000 12 25 40 100 0.37 350 500 350 500 100 MT#5 X:20, Z:24 7.5/12 X:2.5, Z:2.5 0.75 320 x 166 x 185 355 x 160 x 180 320 x 166 x 185 355 x 160 x 180 4,100 4,500 4,100 4,500 285*229 305*229 285*229 305*229 ※Specification is subject to change without prior notice.

1※Thickness of jaw, tool and retract room have been reserved.

2※Chip conveyor is included. -

Standard Accessories

- U sleeve ø16,20,25,32 per size 1 pc

- ID sleeve ø6,8,10,12,16,20,25 per size 1 pc

- OD tool holder 2 sets

- ID tool holder 3 sets

- U-drill tool holder 1 set

- MT#2, 3 sleeve per size 1 pc

- Work light

- Full enclosure

- Heat exchanger

- Auto lubricator

- Hydraulic chuck (1 set hard jaw, 3 sets soft jaw)

- Programmable tailstock

- Side type chip conveyor (with tank)

- Tool box with tool kits

Optional Accessories- Auto door

- Auto bar feeder

- Air-conditioner

- Tool probe

- Oil-water separator

- Oil skimmer

- Part catcher

- VDI40-5480 tool holder 0°(run out) / 90°