Menu

Products

Horizontal lathe

High Speed Precision Lathe

Precision Heavy-Duty Lathe

Heavy-Duty Lathe

PC Base

CNC Lathe Machine

Vertical Machining Center

Linear Way

Box Way

Gearhead Way

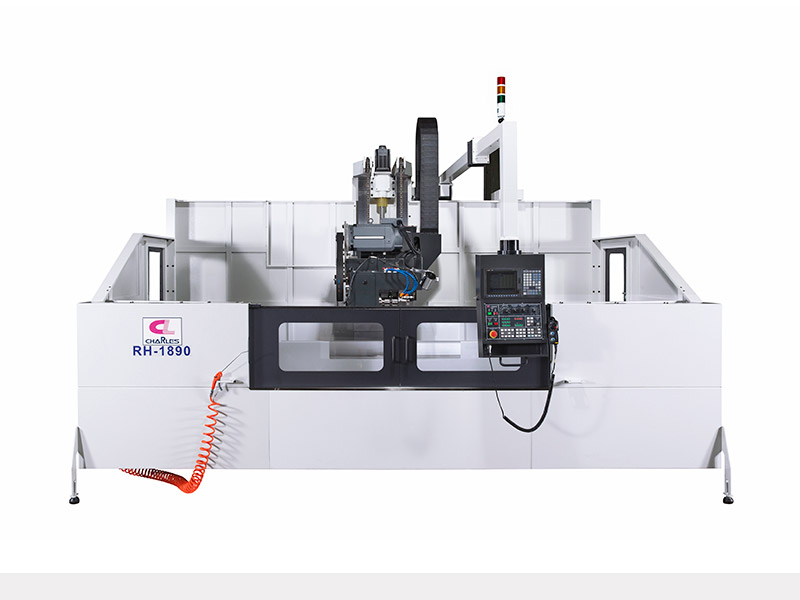

High Speed Bridge Type

Rack Hobbing Machine

RH-1600

home > products > Rack Hobbing Machine > RH-1600

-

- All the gears in headstock are carburized by heat treatment and grinded accurately in order to extend life.

- With the wide spindle motor so could achieve high performance under low speed.

- Bearings in headstock are ball bearings which can withstand heavy cutting. Due to their larger contact area advantage, ball bearings could withstand greater axial and radial cutting force.

-

SPECIFICATIONS Unit Travel X-Axis travel mm Y-Axis travel mm Z-Axis travel mm Table Area mm Max. Table load kgs T-slot dia. mm Distance Arbor center to table surface mm Arbor Tooth module Arbor diameter mm Arbor speed (variable) RPM Fixing key for hob and arbor engagement (Width x Height) mm Hob diameter mm Max. Hob width mm Feeding Rapid feed speed m/min Controller Mitsubishi controller (8.4") Motor Spindle motor (Wide) HP Feed motor KW CNC lathe size (Length x Width x Height) cm Net weight kgs Suitable container RH-1600 1,600 800 800 1,800 x 810 2,000 CD 125 x 18 x 7T 80-750 M0.5-M12 50 150 12 x 8 145-200 100 X:20, Y:20, Z:15 E70 15 X:4.5, Y:4.5, Z:4.5 470*330*350 14,500 20'FR ※Specification is subject to change without prior notice. -

STANDARD ACCESSORIES

- Alarm light

- Arm type ATC

- Remote MPG

- Full enclosure

- Rigid tapping

- Spindle oil cooler

- RS232 Interface

- Heat exchanger

- Coolant flushing system

- A.I.Contour Control

- Auto lubricating system

- Auto power off system

- Metal telescopic cover

- Double screw type chip conveyor (with tank)

- Level adjusting bolts and pads

- Spindle auto flush / air blast device

- Handle flush and air blast device

- Tool box with tool kits

OPTIONAL ACCESSORIES- Air-conditioner

- Coolant ring

- Tool setter

- Oil skimmer

- Rotary table

- C.T.S (coolant thrugh spindle)

- Boat type chip conveyor (with tank)