Menu

Products

Horizontal lathe

High Speed Precision Lathe

Precision Heavy-Duty Lathe

Heavy-Duty Lathe

PC Base

CNC Lathe Machine

Vertical Machining Center

Linear Way

Box Way

Gearhead Way

High Speed Bridge Type

Rack Hobbing Machine

LVC-855/860/1160

home > products > Linear Way > LVC-855/860/1160

-

- Through pre-tightening treatment, there’s none gap between guideways. And machine operating life is longer than box way machines.

- With roller type linear guideway to make up the disadvantage of smaller cutting performance. Through the linear contact between rolling elements, guideway and blocks, there’s only slight elastic deformation on the rolling elements when they withstand high loads, so the whole linear guideway could achieve the performance of high rigidity and high load capacity in four directions. Besides, because of feature of high rigidity, machining accuracy could be increased a lot to achieve the requirement of high accuracy. Plus the super high load capacity to extend the life of linear guideway.

- Suitable for machining various type of precision parts, smaller precision molds and high accuracy requirement workpiece.

-

SPECIFICATIONS Unit Travel X-Axis travel mm Y-Axis travel mm Z-Axis travel mm Linear guide way X-Axis Y-Axis Z-Axis Ball screw X-Axis Y-Axis Z-Axis Table Area mm Max. Table load kgs T-slot dia. mm Spindle Spindle taper Spindle speed and driving method RPM Spindle speed and driving method* OP RPM Distance Spindle nose to table surface mm Spindle center nose to column mm Tool Tool capacity Max. Length of tool mm Max. Dia of tool mm Max. Weight of tool kgs Tool change time sec Feeding Rapid feed speed m/min Controller Mitsubishi controller (10.4") Fanuc controller (8.4") Motor Spindle motor HP Feed motor Mitsubishi controller (10.4") KW Fanuc controller (8.4") KW Machine size( Length x Width x Height ) cm Net weight kgs Suitable container LVC-855 LVC-860 LVC-1160 800 800 1,100 500 600 500 600 RGW30 RGW35 RGW30 RGW45 RGW35 RGW45 R32 x P12 R40 x P12 R32 x P12 R40 x P12 R32 x P12 R40 x P12 900 x 500 1,000 x 600 1,200 x 600 350 400 600 CD 100 x 16 x 5T CD 100 x 18 x 5T BT40 10,000 Belt type 10,000 / 12,000 / 15,000 Direct type 150-750 600 24 300 135 8 1.31 (60HZ) X:36, Y:36, Z:24 M80 0i-MF B8 10 15 X:2.0, Y:2.0, Z:3.0 X:2.0, Y:2.0, Z:3.5 X:1.8, Y:1.8, Z:2.5 X:3.0, Y:3.0, Z:3.0 225*245*225 262*212*272 292*212*272 4,150 5,000 5,400 40'HQ ※Specification is subject to change without prior notice. -

STANDARD ACCESSORIES

- Alarm light

- Arm type ATC

- Remote MPG

- Full enclosure

- Rigid tapping

- Spindle oil cooler

- Tool box with tool kits

- RS232 Interface

- Heat exchanger

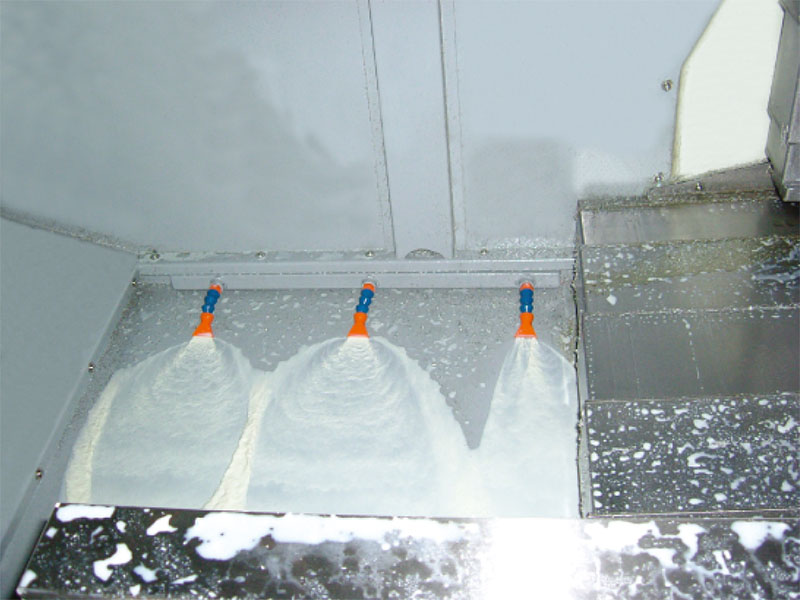

- Coolant flushing system

- A.I.Contour Control

- Auto lubricating system

- Auto power off system

- Metal telescopic cover

- Cutting liquid defector

- Boat type chip conveyor (with tank)

- Level adjusting bolts and pads

- Spindle auto flush / air blast device

- Handle flush and air blast device

OPTIONAL ACCESSORIES- Air-conditioner

- Coolant ring

- C.T.S (coolant thrugh spindle)

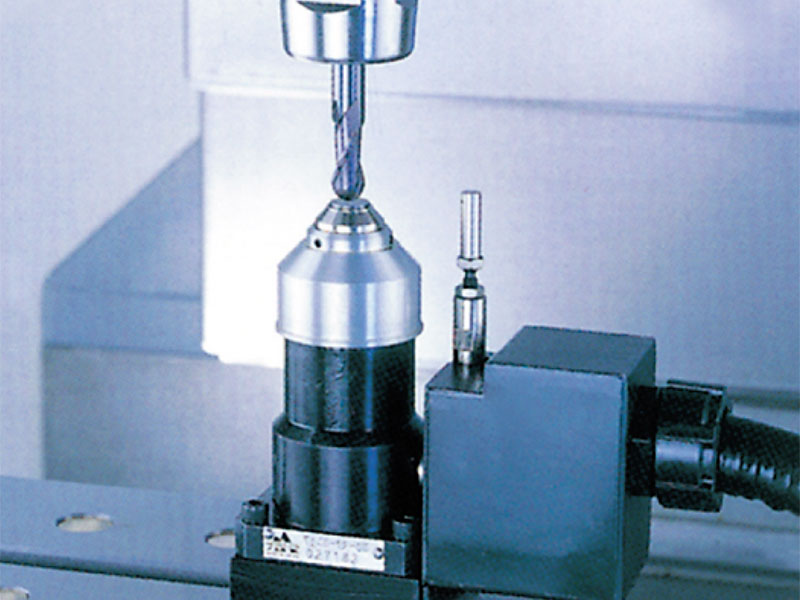

- Tool setter

- Rotary table

- Oil-water separator

- Spin window